KKZ rollers of METEOR series

Currently, the model range of the FeatAgro press rollers is represented by rollers with a working width of 6 or 9 meters with one of two types of the working bodies:

|

Сrosskill roller (KKSH) |

Cambridge roller (KKZ) |

Sound PRO! arguments for the METEOR press rollers:

- high productivity at low operating costs;

- aggregated with tractors of class 1.4 - 2;

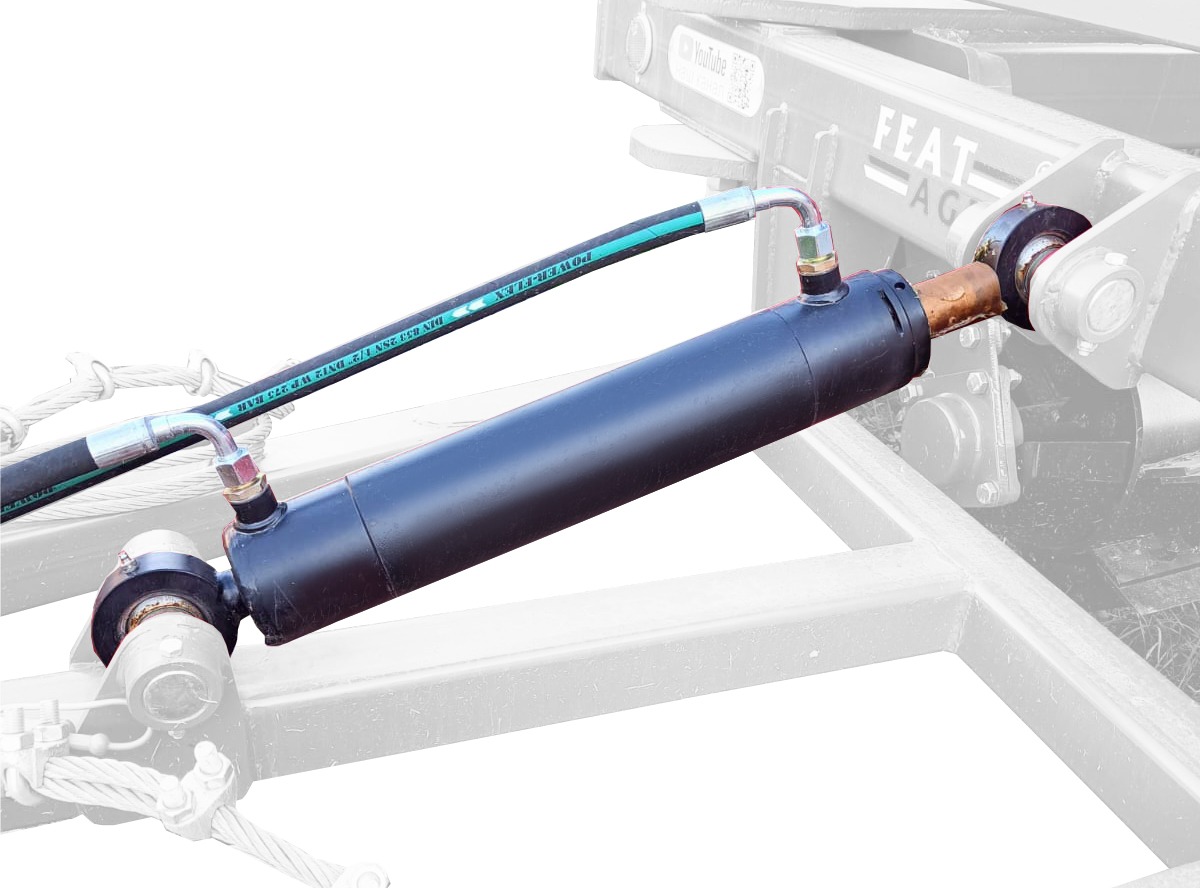

- the units are hydraulically equipped, therefore they are quickly transferred to the operating or transport position;

- the availability of transport wheels allows to quickly move from one field to another one and over long distances;

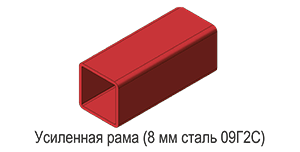

- the frame is made of 09G2S structural steel, which increases the service life and reliability of the machines;

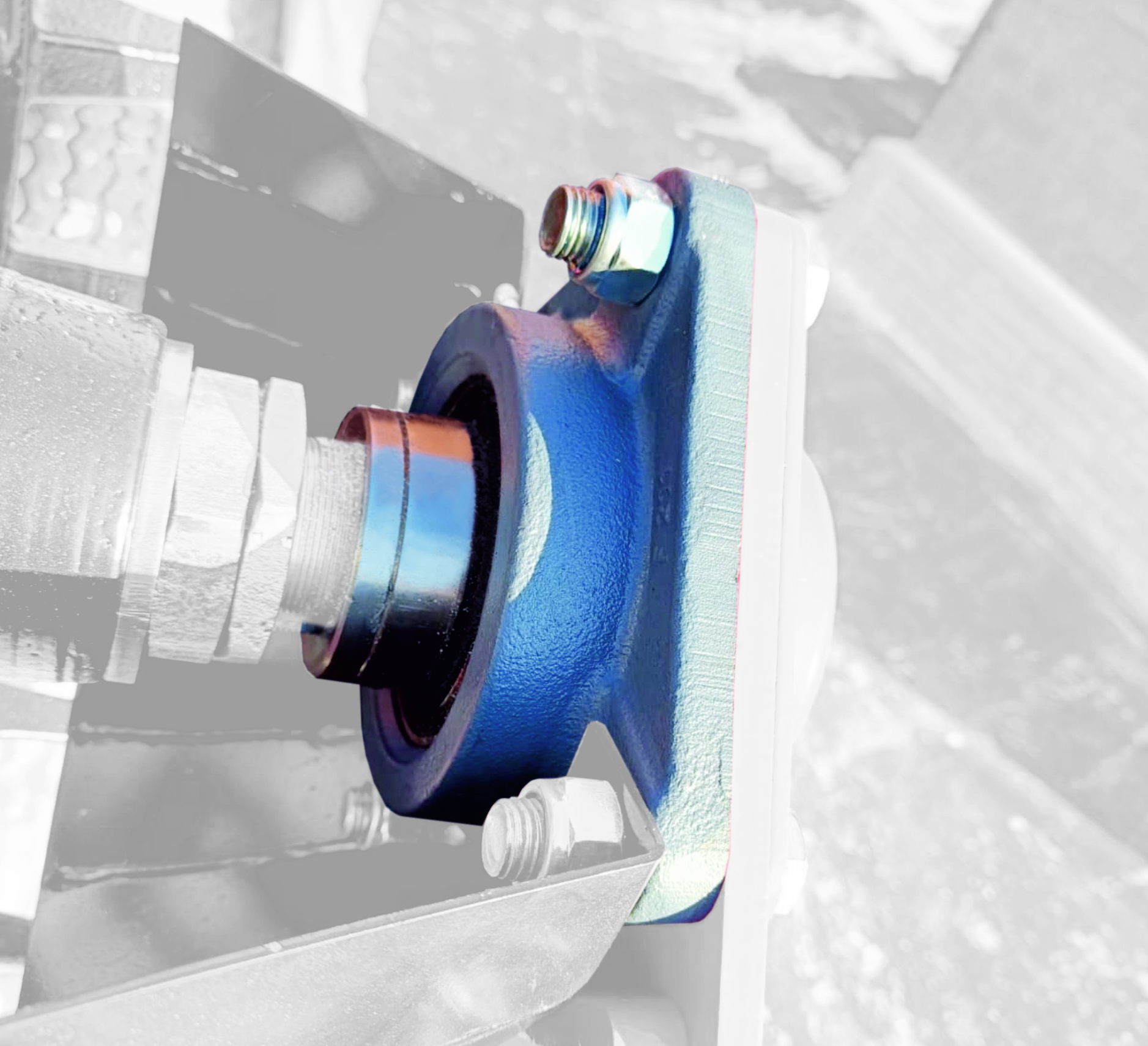

- the rollers have reliable maintenance-free bearing assemblies manufactured by FKL (Serbia) with a special triple seal. They have a direct agricultural purpose and meet all the operation requirements in extreme conditions.

At the same time:

Crosskill rollers (KKSH):

- efficiently break up clods;

- destruct the surface crust of the soil;

- compact the upper layers of the treated surface, which improves the seed contact with the soil and restores the capillary feeding of seeds;

- produce partial leveling of the treated surface;

- have low tractive effort which leads to the reduced fuel consumption;

- are suitable for both pre-sowing and post-sowing soil compaction.

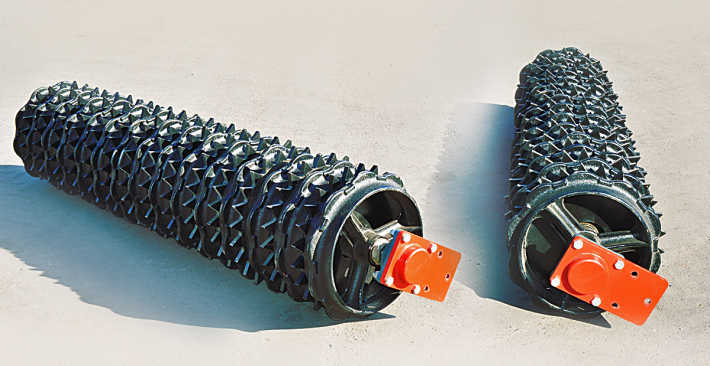

Cambridge rollers (KKZ):

- have a higher specific pressure on the soil, in contrast to lightweight rollers, which gives more effective leveling, breaking up clods after the main/pre-sowing treatment, increasing the moisture conservation. As a result, more favorable conditions for the operation of seeders are created, including the reduced slipping and sinking of the support wheels of the seeder when sowing in wet soils;

- reduce the soil subsidence after the emergence of seedlings;

- increase the uniformity of planting seeds in the soil, especially of small-seeded crops;

- the post-sowing compaction improves the seed contact with the soil, restores the capillary feeding of the seeds and reduces the evaporation of moisture from the soil;

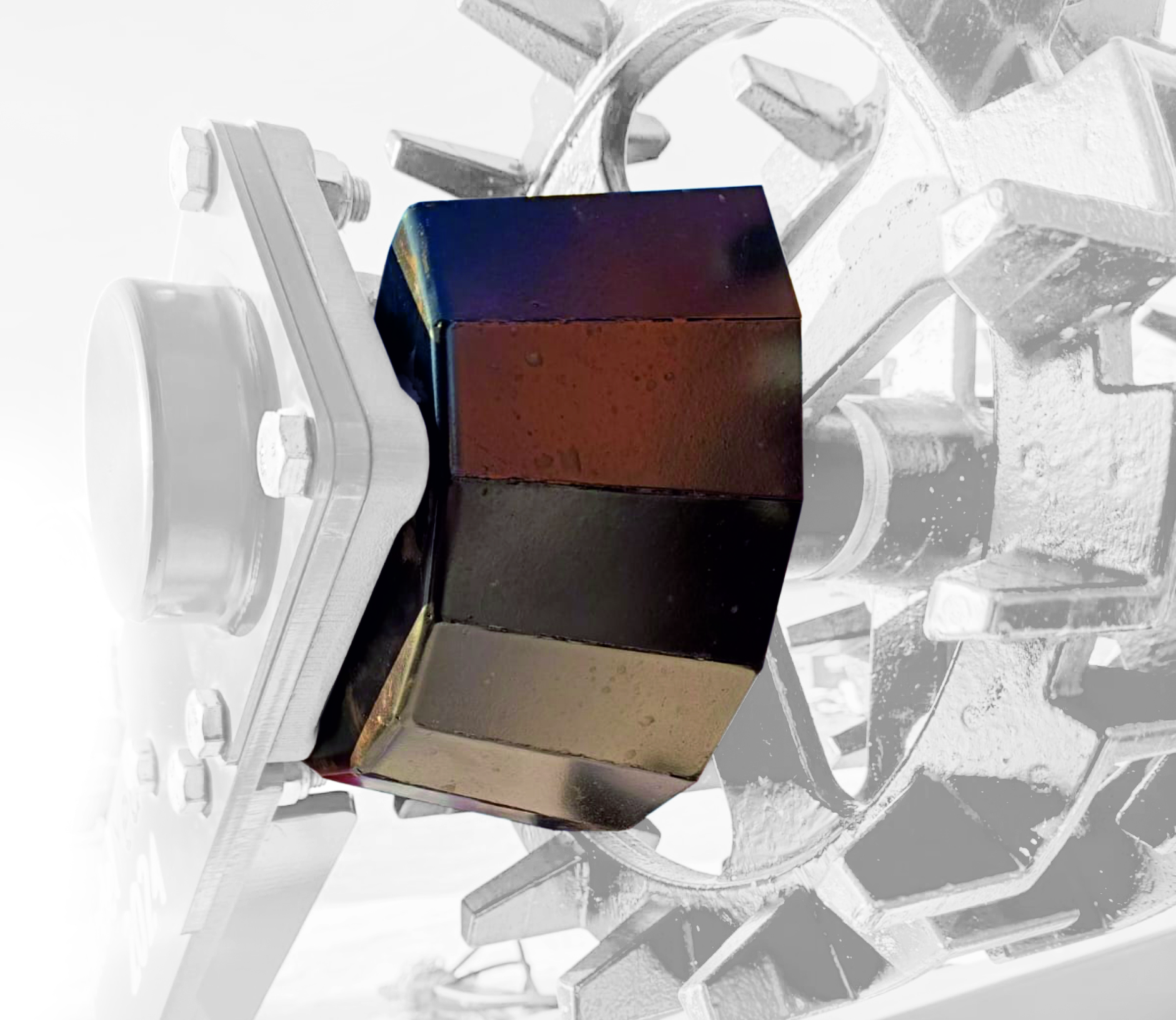

- work on heavier and wetter soils due to the availability of rotating discs – a self-cleaning effect.

- Рама изготовлена из конструкционной стали 09Г2С, что увеличивает срок эксплуатации и надежность машин;

- Наличие транспортных колес позволяет быстро переезжать с поля на поле и на значительные расстояния;

- Агрегаты гидрофицированные, поэтому быстро переводятся в рабочее или транспортное положение;

- Рабочие органы катка ККЗ-6 (480мм) — диски и зубчатые кольца. Взаимоперемещение колец относительно дисков позволяет секциям катка самоочищаться во время работы.

- Катки имеют надежные подшипниковые узлы производства FKL (Сербия) со специальным тройным уплотнением, не требующие обслуживания. Они имеют прямое сельскохозяйственное назначение и отвечают всем требованиям эксплуатации в экстремальных условиях.

- Подшипниковая группа катка защищена кожухом для препятствия наматывания пожневных остатков.

|

Parameter name |

KKZ-6 |

|

|---|---|---|

|

Weight, kg |

2600 |

|

|

Productivity, ha/hour |

Up to 7,2 |

|

|

Operating speed, km/h, not more than |

12 |

|

|

Transport speed, km/h, not more than |

15 |

|

|

Operating width, m |

6 |

|

|

Number of sections, pcs. |

3 |

|

|

Number of blades, pcs. |

96 |

|

|

Distance between cutting edges of blades, mm |

200 |

|

|

Number of operating staff, persons. |

1 |

|

|

Dimensions, mm: |

|

|

|

- length |

3520 |

|

|

- width |

6370 |

|

|

- height |

1000 |

|

|

- diameter |

460/480 |

|

|

Dimensions in the transport position, mm: |

|

|

|

length |

4900 |

|

|

width |

2350 |

|

|

height |

1720 |

|

|

Recommended drawbar category of tractors, p.f. |

1,4 - 2 |

|